Our Top Class High Quality Products

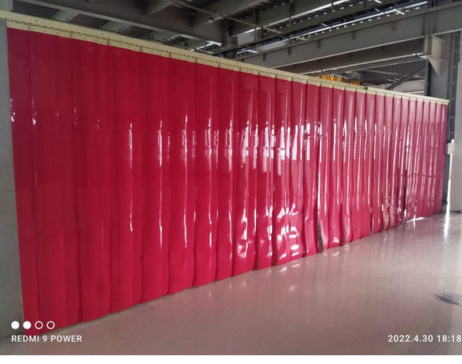

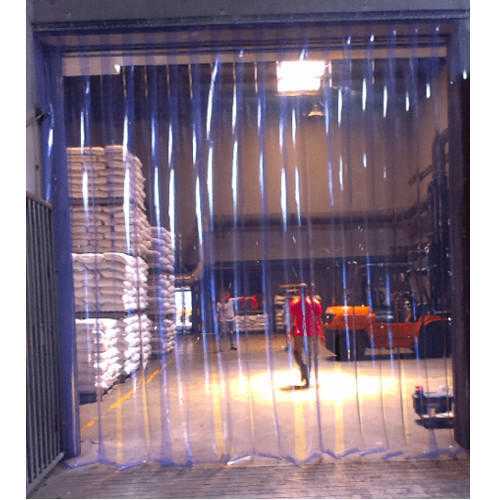

They consist of a series of overlapping PVC strips that are usually hung from an overhead track to create a curtain-like partition. These curtains are commonly used in various industrial, commercial, and even residential settings for a wide range of purposes. Here are some key features and applications of PVC strip curtains: PVC strip curtains are commonly used in industrial environments such as manufacturing plants, warehouses, and distribution centers. They can be installed in doorways to separate different work areas, prevent cross-contamination, and reduce noise pollution. Cold Storage and Freezer Rooms: PVC strip curtains are highly effective in cold storage facilities, walk-in freezers, and refrigerated trucks. They help to maintain the desired temperature inside these areas while allowing for easy access.

Food Processing and Packaging PVC strip curtains are utilized in food processing facilities to create hygienic barriers between various processing areas, helping to meet food safety regulations and prevent contamination. Cleanrooms and Laboratories: In cleanrooms and laboratories, where maintaining specific environmental conditions is crucial, PVC strip curtains are used to control airflows and minimize particle and contaminant infiltration. Retail and Supermarkets: Many supermarkets and retail stores use PVC strip curtains on their refrigerated display cases to keep cold air from escaping and maintain food freshness.

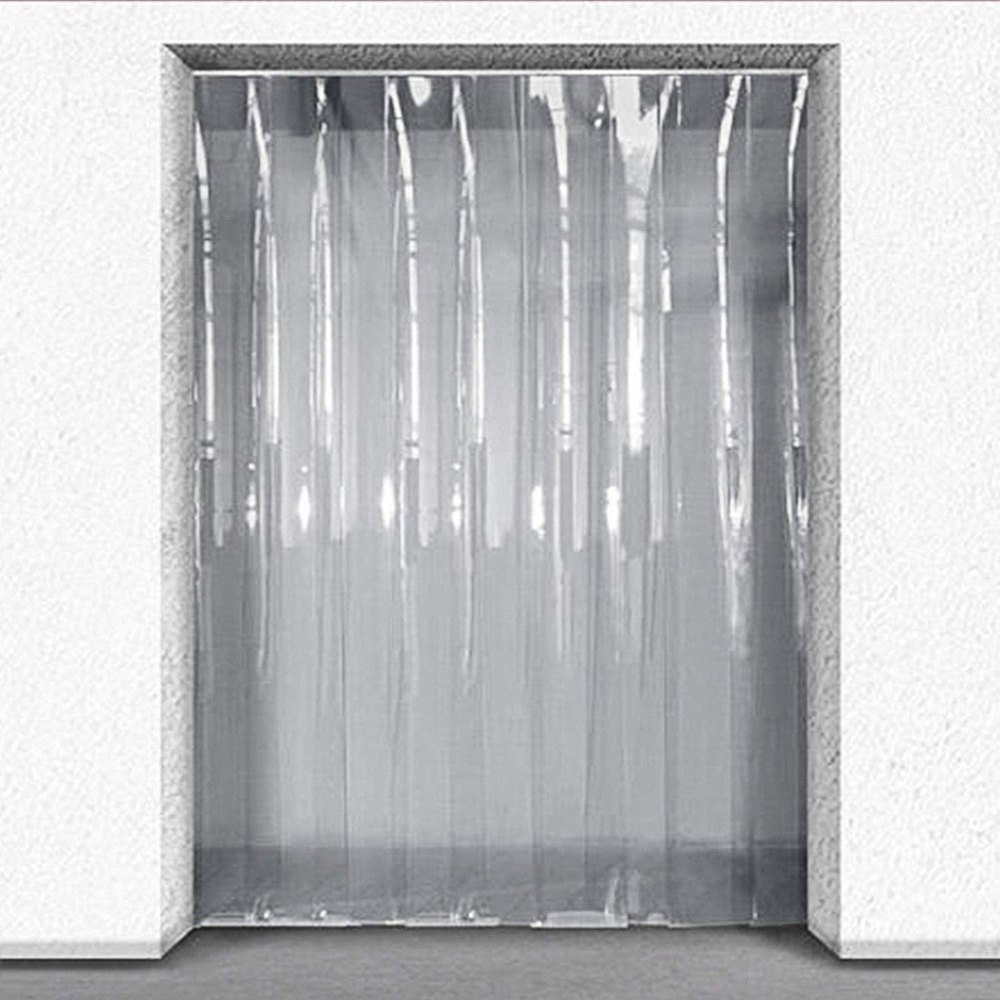

These strips are typically made from materials like PVC (Polyvinyl Chloride), vinyl, or other plastics. Strip curtains are hung from an overhead track or mounting bar, creating a barrier that allows easy passage for people, vehicles, or equipment while keeping out dust, insects, noise, and maintaining temperature control in certain environments. Flexibility Strip curtains are highly flexible due to the individual overlapping strips. This design allows for easy movement through the curtain without the need to open and close a traditional solid door.

Transparency The strips are usually transparent, providing clear visibility on both sides of the curtain. This feature is helpful for safety, as it allows people to see potential hazards before passing through. Temperature Control: Strip curtains help to maintain temperature differences between two areas, making them ideal for areas where climate control is necessary. For instance, they are widely used in cold storage facilities and freezer rooms to retain cold temperatures.

Energy Efficiency by acting as a barrier to airflow, strip curtains contribute to energy efficiency by reducing heat loss or gain in temperature-controlled environments. This is particularly beneficial in industrial settings where doors are frequently opened and closed.

Insect and Dust Control: Strip curtains are effective at keeping out insects, dust, and pollutants, making them valuable in areas where cleanliness and hygiene are crucial, such as food processing facilities and cleanrooms. Noise Reduction: Strip curtains can also help reduce noise pollution by acting as a partial sound barrier, making them useful in industrial settings with loud machinery or processes.

The roll contains multiple individual PVC strips, usually transparent and of various

widths and thicknesses, which can be cut to the desired length for specific applications. PVC strip rolls are commonly used in industrial, commercial, and even residential settings for creating barriers and partitions while allowing easy access and visibility. They offer similar features and applications as PVC strip curtains, but with the advantage of being customizable in terms of length and width.

Flexibility PVC strip curtains, PVC strip rolls are highly flexible, allowing easy passage for people, vehicles, or equipment without the need for manual operation. Transparency: The individual PVC strips in the roll are transparent, providing clear visibility on both sides, promoting safety, and allowing people to see potential hazards before passing through.

Temperature Control: PVC strip rolls are used to create barriers that help maintain temperature differences between two areas, making them suitable for temperature- controlled environments, cold storage facilities, and freezer rooms.

Energy Efficiency: By acting as a barrier to air exchange, PVC strip rolls contribute to energy efficiency by reducing heat loss or gain, especially in settings with frequent door openings.

Insect and Dust Control: PVC strip rolls effectively keep out insects, dust, and pollutants, making them valuable in maintaining cleanliness and hygiene in various environments, such as food processing facilities. Noise Reduction: Similar to strip curtains, PVC strip rolls can help reduce noise pollution by acting as a partial sound barrier, making them useful in industrial settings with loud machinery or processes.

Welding generates intense light, heat, and sparks, which can cause eye injuries, burns, and skin damage if proper safety measures are not in place. Welding curtains are designed to create a physical barrier that contains and blocks the harmful elements produced during welding. Flame Retardant Material: Welding curtains are made from flame-retardant materials, such as fire-resistant PVC-coated fabrics or heavy-duty welding blankets, that can withstand high temperatures without catching fire. UV and Infrared Protection: Welding curtains are designed to block harmful ultraviolet (UV) and infrared (IR) radiation emitted during welding, which can cause eye damage and skin burns.

Transparency: While welding curtains primarily block harmful light, they are usually transparent or semi-transparent to allow visibility of the welding area, enabling welders to maintain visual contact with their work. Durability: Welding curtains are built to be durable and resistant to wear and tear, as welding environments can be harsh and demanding.

Portable and Flexible: Welding curtains are often lightweight and portable, allowing them to be easily moved and positioned as needed to create safe work zones. Versatility: Welding curtains come in various sizes, shapes, and mounting options, making them suitable for various welding applications and workspaces.

At Top Tex Technologies, we understand the paramount importance of safety and productivity in the welding industry. That’s why we proudly introduce our state-of-the-art Welding Booth, a purpose-built solution designed to provide welders with a secure and optimized working environment.

Safety is at the core of our Welding Booth design. Equipped with advanced ventilation and filtration systems, our booths effectively capture and remove welding fumes and airborne particles, safeguarding welders from harmful exposures. The enclosed structure ensures that sparks and debris are contained, reducing the risk of accidents and providing a secure space for welding operations.

At Top Tex Technologies, we understand that each welding project is unique. Our Welding Booths are highly customizable, catering to your specific requirements. Whether you need a compact booth for small-scale operations or a larger booth to accommodate multiple welders, our team can tailor the booth to match your preferences and space constraints.

As industry leaders, we take pride in delivering Welding Booths of the highest quality. Each booth is constructed with durable and sturdy materials, ensuring longevity and resistance to wear and tear. Our commitment to craftsmanship means that you can rely on our Welding Booths for long-term use and reliable performance.

It is made from Polyvinyl Chloride (PVC) material, which provides flexibility, transparency, and durability, making it well-suited for industrial applications. Temperature Control: Industrial PVC strip curtains are effective in controlling temperature differences between different areas. They help to retain heat in heated zones and prevent the intrusion of cold air into temperature-sensitive areas, such as warehouses, manufacturing plants, and cold storage facilities.

Energy Efficiency: By reducing the exchange of air between areas, industrial PVC strip curtains contribute to energy conservation, as they help to minimize heat loss or gain when doors are frequently opened and closed.

Environmental Separation: These curtains create a physical barrier that prevents the movement of dust, dirt, fumes, and contaminants between different work zones. They help maintain cleanliness and hygiene, making them suitable for use in food processing facilities, cleanrooms, and laboratories. Noise Reduction: Industrial PVC strip curtains also offer some level of noise reduction, which can be beneficial in industrial settings with loud machinery or processes. Easy Access: The flexibility of PVC strips allows for easy passage of personnel, vehicles, and equipment without the need to manually open and close a traditional door.

Safety: Industrial PVC strip curtains improve safety by providing visibility of potential hazards on the other side before passing through. Chemical Resistance: PVC strip curtains are often resistant to chemicals, oils, and some solvents, making them suitable for environments where exposure to such substances may occur.

These curtains are essential for maintaining temperature control, preventing temperature fluctuations, and preserving the quality of stored goods in low- temperature environments. Temperature Control Freezer curtains are highly effective at maintaining temperature differences between the freezer or cold storage area and the ambient surroundings. They help to retain the cold air inside the freezer and prevent warm air from entering, thereby ensuring a consistent and stable temperature.

Energy Efficiency by acting as a thermal barrier, freezer curtains contribute to energy efficiency by reducing the loss of cold air when the freezer door is opened and closed frequently. This helps to conserve energy and lower operating costs.

PVC Material Freezer curtains are typically made from durable and flexible PVC material, which provides excellent insulation and maintains its properties even in low-temperature environments. Transparency: The PVC strips used in freezer curtains are usually transparent, allowing visibility through the curtain and enabling employees to see what is on the other side before entering or exiting the freezer. Easy Access The flexible PVC strips allow for easy access for personnel and equipment to move in and out of the freezer without the need to open and close a solid door.

Durability Freezer curtains are designed to withstand low temperatures, preventing cracking or damage in freezing conditions. Frost and Condensation Control: Freezer curtains help to minimize frost and condensation build-up on the freezer door, which can be common with traditional solid doors.

The strips are usually made from materials like PVC (Polyvinyl Chloride), vinyl, or other plastics. Flexible strip curtains are widely used in various industrial, commercial, and even residential settings for creating partitions, barriers, and doorways with easy access and visibility. Flexibility as the name suggests, the primary feature of a flexible strip curtain is its ability to bend and move easily. This flexibility allows people, vehicles, or equipment to pass through without the need to open and close a traditional solid door. Transparency The individual strips are usually transparent or semi- transparent, providing clear visibility on both sides of the curtain. This feature enhances safety by allowing people to see potential hazards before passing through.

Temperature Control Flexible strip curtains help in controlling temperature differences between different areas, making them ideal for environments where climate control is crucial, such as in cold storage facilities or temperature-sensitive processes.

Environmental Separation: They create a physical barrier that prevents the movement of dust, dirt, fumes, and contaminants between different work zones, making them valuable in maintaining cleanliness and hygiene. Noise Reduction Flexible strip curtains can also help reduce noise pollution by acting as a partial sound barrier, making them useful in industrial settings with loud machinery or processes.

Customizable Flexible strip curtains come in various sizes, widths, and thicknesses to suit specific requirements, and they can be easily trimmed or adjusted to fit different door or opening sizes.

They are similar to standard industrial PVC strip curtains but are specifically tailored to withstand extremely low temperatures and maintain the desired temperature in cold rooms, walk-in freezers, and refrigerated areas. Cold room PVC strip curtains are made from PVC material that is specifically formulated to remain flexible and durable in freezing temperatures. This allows them to effectively seal off cold storage areas and maintain the desired low temperatures.

Energy Efficiency: By providing a barrier to the movement of cold air, cold room PVC strip curtains help conserve energy by reducing heat transfer and minimizing temperature fluctuations. This results in reduced energy consumption and lower operating costs. The PVC strips used in these curtains are usually transparent or semi- transparent, allowing visibility on both sides of the curtain. This feature enhances safety by enabling people to see what’s on the other side before entering or exiting the cold room.

Easy Access Cold room PVC strip curtains are highly flexible, allowing for easy passage of personnel, carts, and forklifts without the need to open and close a solid door, which helps to improve workflow efficiency.

Frost and Condensation Control The PVC material used in the curtains helps to minimize frost and condensation build-up on the curtain’s surface, maintaining clarity and preventing obstructions to visibility. Resistance to Chemicals: These curtains are often resistant to chemicals, oils, and some solvents, making them suitable for use in environments where exposure to such substances may occur.

These curtains are commonly used in various settings to prevent insects from entering indoor spaces, especially in areas where maintaining a clean and insect-free environment is crucial. Insect and Pest Control: The primary purpose of an anti-insects PVC strip curtain is to create a physical barrier that prevents insects, flies, and pests from entering indoor areas. This is particularly important in settings like food processing facilities, restaurants, commercial kitchens, warehouses, and other spaces where hygiene and cleanliness are critical.

Transparency: The PVC strips used in anti-insect’s curtains are typically transparent, allowing for clear visibility on both sides of the curtain. This feature enables people to see potential insects or hazards before passing through, improving safety. Energy Efficiency: Similar to other PVC strip curtains, anti-insects PVC strip curtains also help with energy efficiency by minimizing air exchange between indoor and outdoor spaces, which can reduce heating or cooling costs.

Temperature Control While their primary function is to keep insects out, anti-insects PVC strip curtains can also help maintain temperature differences between areas, contributing to temperature control in certain environments. Easy Access: The flexible nature of the PVC strips allows for easy movement of personnel, carts, and equipment through the curtain without the need to open and close a solid door.

Durability: Anti-insects PVC strip curtains are designed to be durable and resistant to wear and tear, even in high-traffic environments. Food Industry: Anti-insects PVC strip curtains are commonly used in food processing facilities, restaurants, and commercial kitchens to maintain hygiene and prevent insect contamination in food preparation and storage areas. Warehouses and Storage Areas They are employed in warehouses and storage spaces to prevent insects and pests from entering and damaging stored goods. Pharmaceutical and Healthcare: Anti-insects PVC strip curtains can be utilized in pharmaceutical facilities, hospitals, and healthcare settings to create insect barriers in cleanrooms and critical areas.

Energy Efficiency: By providing a barrier to the movement of cold air, cold room PVC strip curtains help conserve energy by reducing heat transfer and minimizing temperature fluctuations. This results in reduced energy consumption and lower operating costs. The PVC strips used in these curtains are usually transparent or semi- transparent, allowing visibility on both sides of the curtain. This feature enhances safety by enabling people to see what’s on the other side before entering or exiting the cold room.

Easy Access Cold room PVC strip curtains are highly flexible, allowing for easy passage of personnel, carts, and forklifts without the need to open and close a solid door, which helps to improve workflow efficiency.

Frost and Condensation Control The PVC material used in the curtains helps to minimize frost and condensation build-up on the curtain’s surface, maintaining clarity and preventing obstructions to visibility. Resistance to Chemicals: These curtains are often resistant to chemicals, oils, and some solvents, making them suitable for use in environments where exposure to such substances may occur.